How Long Will a 316 Flue Liner Last When Burning Coal?: Knowing how long different parts of a chimney system will last is important information to have when installing or maintaining one. The flue liner is one of the essential parts; it is responsible for safeguarding the chimney’s structure, improving safety, and guaranteeing effective functioning. Because of the distinct combustion properties of coal, the choice of flue liner material is crucial for those who burn it. This blog will examine the lifespan of the 316 flue liner, which is a common option for households, in conjunction with coal-burning appliances.

A 316 Flue Liner: What Is It?

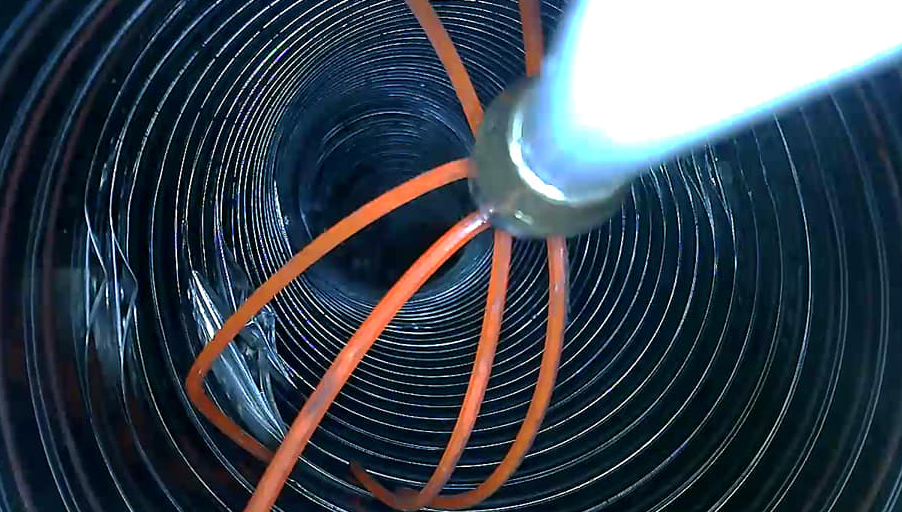

Austenitic stainless steel, specifically the 316-grade variety that includes molybdenum, nickel, and chromium, is used to make 316 flue liners. These components offer improved resistance to corrosion, especially in acidic settings, which makes them a great option for a variety of fuels, such as gas, coal, and wood. When handling the extreme heat and corrosive byproducts of coal combustion, the 316-grade stainless steel’s resilience and tolerance to high temperatures come in handy.

The Effects of Coal Burning on Flue Liners

Although coal is a dense, high-energy fuel, it also releases a number of extremely corrosive byproducts, such as sulfur compounds, which can react with moisture to make sulfuric acid. Particularly vulnerable to damage from this acid are flue liners and other chimney components. As a result, a number of factors affect how long a flue liner used in a coal-burning application lasts:

Coal Quality: While lower-grade coal may include more sulfur and other contaminants that might speed up corrosion, higher-grade coal burns cleaner and produces fewer corrosive byproducts.

Burning Practices: The quantity of acidic condensate produced can be decreased by using proper burning practices, such as keeping the right air-to-fuel ratio and preventing smoldering fires.

Chimney Maintenance: By keeping the chimney system clean and inspected on a regular basis, you may prolong the life of the flue liner by preventing the accumulation of corrosive residues.

Installation Quality: A well installed liner with adequate sealing and insulation will be shielded from corrosive substances for a longer period of time.

Expected Lifespan of a Coal-Powered 316 Flue Liner

A 316 flue liner’s lifespan when burning coal can vary greatly according on the previously listed conditions. You should generally anticipate the following:

Average Lifespan: In a coal-burning application, a 316 flue liner often lasts 10 to 15 years. This is presuming the use of high-quality coal, appropriate burning techniques, and routine maintenance.

Ideal Conditions: A 316 flue liner may survive up to 20 years or longer under ideal circumstances, which include burning high-quality, low-sulfur coal, careful chimney maintenance, and correct installation.

Hard Conditions: The lifespan of the liner may be drastically shortened, possibly lasting only five to ten years, if low-grade coal is used, the chimney is not properly maintained, or it is not appropriately insulated.

Clues That Your Flue Liner Needs to be Replaced

Flue liners will eventually need to be replaced, even with the best upkeep. The following indications indicate that the life of your 316 flue liner may be coming to an end:

Corrosion: The liner is deteriorating if there are obvious indications of rust or corrosion on it or if metal flakes are discovered after cleaning.

Cracking: The liner clearly needs to be replaced if there are any noticeable cracks or splits in it.

Poor Draft: A damaged liner may be the cause of a decrease in the chimney’s function, which could manifest as a decreased draft or an increase in smoke within the house.

Increased Maintenance Issues: If you observe that the coal burns less efficiently or that the chimney needs to be cleaned more frequently,

Increasing the 316 Flue Liner’s Life

The following upkeep advice can help your 316 flue liner last as long as possible:

Routine Cleaning: If you use your chimney a lot, have it professionally cleaned at least once a year, perhaps more frequently.

Annual Inspections: Arrange annual inspections to identify any problems early on, before they escalate.

Use High-Quality Coal: To lessen the corrosive effects on the liner, if feasible, choose high-grade, low-sulfur coal.

Ensure Appropriate Installation: Verify that a professional installed your flue liner with sufficient sealing and insulation.

Conclusion

For coal-burning chimneys, a 316 flue liner is a sturdy and dependable option that strikes a compromise between cost and longevity. Even the greatest materials will eventually wear down due to the aggressive nature of coal combustion. You can guarantee the longevity and effectiveness of your chimney system for many years to come by being aware of the elements that affect your flue liner’s lifespan and taking preventative measures to maintain it.

If you burn coal, be sure to monitor the state of your chimney and plan to replace your flue liner in ten to fifteen years, or sooner in severe cases. This period can be extended by spending money on high-quality fuel and routine maintenance, which will keep your house secure and warm.